Sheet Metal Finishing

In the world of manufacturing and steel and metal fabrication, the process of finishing is as important as getting and arriving at the best and the most exact measurements and dimensions for the product or the output.

Our world today is dominated by the different kinds and types of steel, metal, and alloy and they all make up a huge percentage of the things we use on a regular and on a normal basis. From our computers, our mobile phones, our refrigerators, air-conditioning units – to our cars, airplanes, and even the buildings and the houses we live in, it’s all around us.

Imagine if all the steel and the metal we use are not finished – they’re just left raw like how their natural state was – how do you think everything would look like? How different would everything around us seem?

Sheet metal finishing is the same idea; the only difference is that this type of finishing is for sheet metals and other types of basic and simple metallic parts and components. There is a wide array of sheet metal finishing procedures that can be done and we here at Michigan Contract Manufacturing Team are ready to impart you with that knowledge.

Overview of Sheet Metal Finishing

If you still can’t get a full grasp of what sheet metal finishing is, then we will try to define and describe it in the simplest way we can. Sheet metal finishing is the process of placing and integrating some type of coating on the exterior of the outer surface of metal sheets.

The finish would depend on how the client wants it – if the client wants a matte finish, then there’s a specific finish to it; if the client wants and needs a glossy and a textured finish, there’s a specific finish to it.

Here with us at Michigan Contract Manufacturing Team, you can count on us to help you with a wide and comprehensive range of sheet metal finish. There are quite a wide and a vast range of finishes in the industry – here are some of them:

Metal Plating

The process of metal plating, obviously, has a goal of making the exterior of the surface of the product or the steel metal plate. This process involves the material being submerged into a chemical solution and is electrocuted – this current will be the one to serve as the catalyst of the coating.

Here are some of the advantages of metal plating:

- Keeps the product from being corroded and scratched easily

- It improves the overall durability of the sheet metal

- It makes the surface of the sheet metal glossier and better

Buff Polishing

Should your project or your sheet metal need some type of smooth finish, then buff polishing would be the best approach to it. Buff polishing is the process in which the surface of sheet metal is buffed using a circular spinning cloth.

More often than not, the process is used to decorate and to heighten the exterior and the overall exterior of the product. Here are some of the advantages of buff polishing:

- Provides a fine sheen to the product’s exterior

- Usually, the edges of the sheet metal would slightly be rounded due to the friction and the effect of the buffing

Powder Coating

Typically the newest and the most famous of all the finishes, powder coating is the process that applies a finish that is decorative and that is durable at the same time. It’s a process where the dry plastic powder is sprayed in high-speed into the surface of the product.

Here are some of the benefits of powder coating:

- Powder coating is effective in the removal of surface defects

- The overall result can be a glossy, matte, or a textured surface

- It can keep the product or the metal sheet from rusting, corrosion, scratching, and cracking

Sand Blasting

Akin to powder coating, the process of sand blasting would provide a matte finish to the product. The process would involve the splashing or the high-powered spewing of abrasives to the surface or the exterior of a product.

Also termed as bead blasting, sand blasting is effective if you are keeping the surface or the exterior of your products smooth and free from defects. Here are some of the sand blasting benefits:

- Smooth texture and clean finish

- Since it’s matte, it can be free from the regular scratches

- It can get rid of some of the defects because of its uniform texture and coating distribution

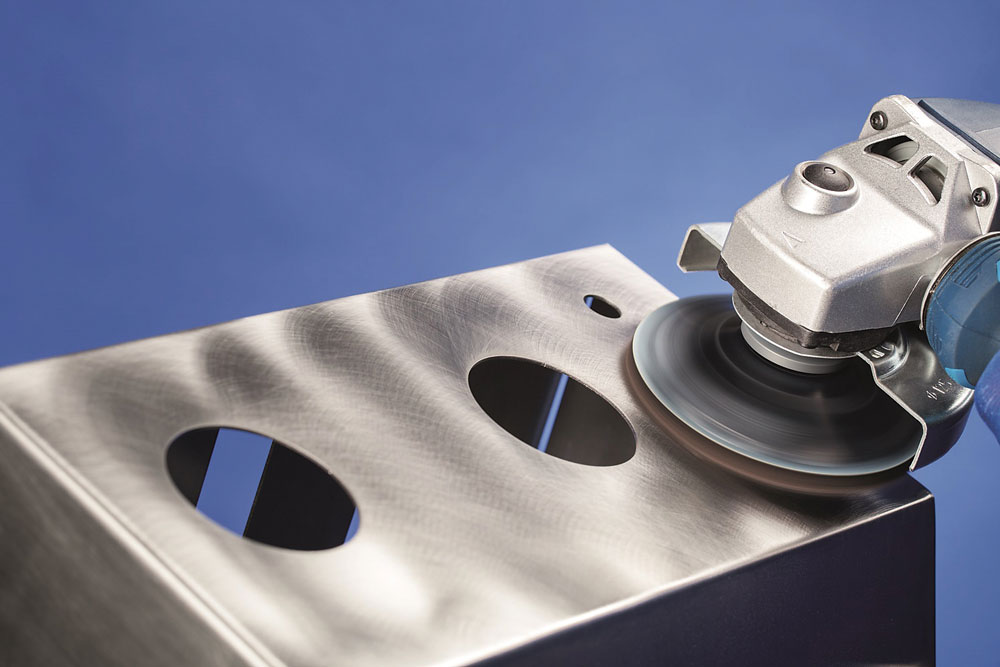

Deburring or Edge Rounding

Last but definitely not the least would be deburring or edge rounding. Similar to buff polishing but this one is considered as the higher version. The main advantage and the main use of this type of finish are to make sure that the edges of the sheet metal or the product is not too sharp or dangerous.

Here are some of the things you can look forward to with edge rounding or deburring:

- Better capability to be painted and be coated

- It’s safer to work with

The types of sheet metal finishing techniques are not just limited to these – there are a lot more! However, these are the most common out of all the types and the kinds. We here at Michigan Contract Manufacturing Team are skilled and adept in performing any of these finishes but we focus highly on our powder coating procedures.

So should you need help in terms of finishing the sheet metals that you have or any other type of product, you can count on us!

Across the entire region and vicinity, we at Michigan Contract Manufacturing Team have been the most trusted and the most relied on company. Give us a call and we will be more than happy to help you with the finish that you need!

Experience world-class quality services without paying for a fortune!

All of these services are the services we have mastered here at Michigan Contract Manufacturing Team. Through decades of experience that our professionals have, you will never find a single error with all our products and our outputs!

Our core offerings and services at Michigan Contract Manufacturing Team includes, but is not limited to, the following below:

We service multiple cities throughout the state of Michigan. We provide all the services listed above, and much more in every city throughout Michigan.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.